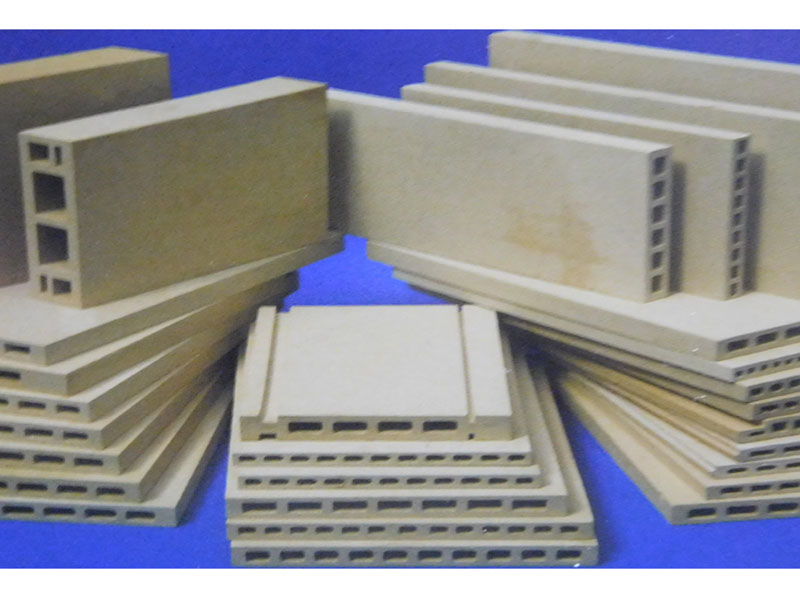

Cordierite Mullite Extruded Batts

[fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="no" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="" margin_bottom="" padding_top="" padding_right="" padding_bottom="" padding_left=""][fusion_builder_row][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" dimension_margin="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_tabs design="classic" layout="horizontal" justified="yes" backgroundcolor="" inactivecolor="" bordercolor="" icon="" icon_position="" icon_size="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_tab title="Description" icon=""]

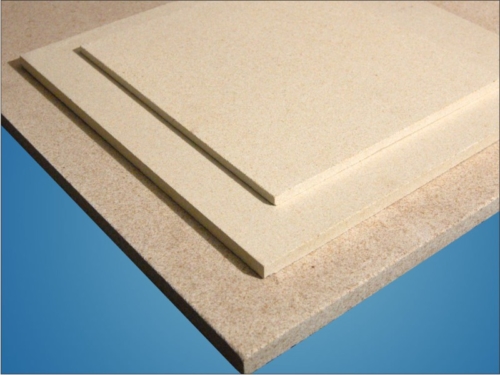

Extruded batts have holes running the length of the cross section and are manufactured using high pressure vacuum extrusion, before being cut and surface-ground to guarantee the highest standard of flatness and dimensional accuracy. Company produce extruded batts and became the first Asian manufacturer. Our extruded batts are now amongst the leading products suppliers in Asia. They are used mainly in the sanitaryware and glass panel industries, but can be found in a number of applications including the biscuit and glost firing of tableware.

[/fusion_tab][fusion_tab title="Application" icon=""]

[/fusion_tab][fusion_tab title="ADVANTAGES" icon=""]

[/fusion_tab][/fusion_tabs][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

Face Impex tiles are estimated to become some of the most easily reached and most durable ceramic material that makes them economical and easily installable. They come with a thin profile side view as slim as 20mm. Face impex have a big range in small format ceramic water proof tiles with different size and color.

See more ideas about Cordierite Mullite Extruded Batts with many different color and looks

#Refractory Materials

- sanitary ware

- glass panel industries,

- glost firing of tableware.

- Excellent energy savings.

- Lighter weight and higher load capacity.

- Excellent distortion resistance at high temperature.

- Suitable for faster firings with better bearing capacity for hot and cold extremes.

| With the same weight, the extruded batt provides many times more carrying capacity then the solid batt | |||

| Thickness of extruded batts | 25mm | 38mm | 46mm |

| Corresponding thickness of solid batts | 16mm | 21mm | 23mm |

| Carrying capacity of extruded batts | 3 times of solid batt | 5 times of solid batt | 8 times of solid batt |

- Weight reduction of approximately 35% - 50%, whilst increasing the load capacity of the batt. For example, a 38mm-thick extruded batt has the same weight as a 23mm-thick pressed batt of the same size, but can bear 5 times the load.

- Energy Savings. Tests have shown that using extruded batts in a shuttle kiln firing glass panels, fuel consumption can be reduced by between 30% and 70%.

- Reduced bend at high temperatures. 1200mm long extruded batts supported by silicon carbide beams have shown virtually no bend during use. This is extremely useful where flatness is critical, such as in the firing of glass panels.

- Their ability to disperse heat is twice that of a solid batt of similar size, allowing them to bear extremes of hot and cold much better, thereby increasing their service life. This makes extruded batts especially suitable for faster firings.

- Thin Extruded Batt

- Large Extruded Batt

- Long Extruded Batt

- Plain Extruded Batt

- Perforated Extruded Batt

- Cut-out Extruded Batt

- Interlock Extruded Batt

- Special Extruded Batt.

| Thin Extruded Batts – Tools | Large Extruded Batts – Tools |

| Long Extruded Batts – Tools | Plain Extruded Batts – Tools |

| Perforated Extruded Batts – Tools | Cut-out Extruded Batts – Tools |

| Interlock Extruded batts – Tools | Special Extruded Batts – Tools |

Face Impex tiles are estimated to become some of the most easily reached and most durable ceramic material that makes them economical and easily installable. They come with a thin profile side view as slim as 20mm. Face impex have a big range in small format ceramic water proof tiles with different size and color.

See more ideas about Cordierite Mullite Extruded Batts with many different color and looks

#Refractory Materials