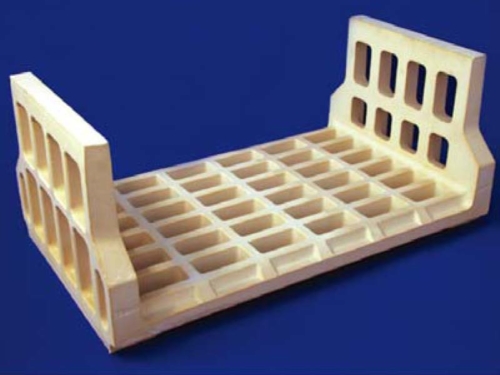

Reaction Sintering Crucible

Out of stock

[fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="no" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="" margin_bottom="" padding_top="" padding_right="" padding_bottom="" padding_left=""][fusion_builder_row][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" dimension_margin="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_tabs design="classic" layout="horizontal" justified="yes" backgroundcolor="" inactivecolor="" bordercolor="" icon="" icon_position="" icon_size="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_tab title="Description" icon=""]

Our Melting Aluminum SiC Crucibles for melting metals and light alloys are manufactured with a mixture, on the basis of graphite, and silicon carbide from which the clay has been eliminated:

1. The thermal conductivity remains stable throughout their usage.

2. Moisture does not affect them at all and, therefore, they should not be preheated or annealed. They always go to the fire as they leave the packing, without any thermal precaution.

3. They resist the sharpest variations in the temperature.

4. Once located in the furnace, in no instance should they be kept on a slow fire. Always take them to the maximum temperature in the shortest possible time.

5. Their shape and sizes do not alter through usage.

6. Special manufacturing processes permit very short terms of delivery.

Controlled Composition Reaction Sintering Crucible Application

The product is widely used in various industrial furnaces, desulphurization equipment, large boilers and other machinery and equipment as well as ceramics, machinery, metallurgy, electronics, chemicals, petroleum, iron and steel industry and so on.

[/fusion_tab][fusion_tab title="Application" icon=""]

[/fusion_tab][fusion_tab title="Advantage" icon=""]

Face Impex tiles are estimated to become some of the most easily reached and most durable ceramic material that makes them economical and easily installable. They come with a thin profile side view as slim as 20mm. Face impex have a big range in small format ceramic water proof tiles with different size and color.

See more ideas about Reaction Sintering Crucible with many different color and looks

#Refractory Materials

- sanitary ware

- glass panel industries,

- glost firing of tableware.

- ceramic tiles

- porcelain tiles

- RBSIC(SiSiC)'s special feature is its ability to maintain high strength from room temperature up to 1,350°C. Also it has very high oxidation resistance, chemical resistance and wear resistance. Used as beam, roller, radiant tube burner and burner nozzle etc.We have cross beam, solid beam and special shape beam. Reaction-bonded silicon carbide beam is applied to the bearing frame of tunnel furnace, shuttle furnace and industrial furnace. reaction-bonded silicon carbide beam is characterized by big high-temperature resistance, no bending deformation and long service life, and is an ideal furnace applied to sanitary ceramics and electro ceramics furnaces. reaction-bonded silicon carbide, with good thermal conductivity, can save energy consumption significantly.

| Item | Unit | Index |

| Application temperature | ℃ | 1380 |

| Density | g/cm3 | ≥ 3.02 |

| Open porosity | % | ≤ 0.1 |

| Bending strength | Mpa | 250 (20℃) |

| Mpa | 280 (1200℃) | |

| Modulus of elasticity | Gpa | 330 (20℃) |

| Gpa | 300 (1200℃) | |

| Thermal conductivity | W/m.k | 45 (1200℃) |

| Coefficient of thermal expansion | K-1×10-6 | 4.5 |

| Rigidity | 13 | |

| Acid and alkali resistance | Excellent |

- We has two factories of 50000 square meters and totally 300 employees to promise the Silicon Carbide and Silicon Nitride Ceramics In Stock best quality control;2. According customers’ demand to design special size;3. Our motivation is --- customers’ satisfaction smile;4. Our believing is --- pay attention to every detail;5. Our wish is ----perfect co-operation.

Face Impex tiles are estimated to become some of the most easily reached and most durable ceramic material that makes them economical and easily installable. They come with a thin profile side view as slim as 20mm. Face impex have a big range in small format ceramic water proof tiles with different size and color.

See more ideas about Reaction Sintering Crucible with many different color and looks

#Refractory Materials