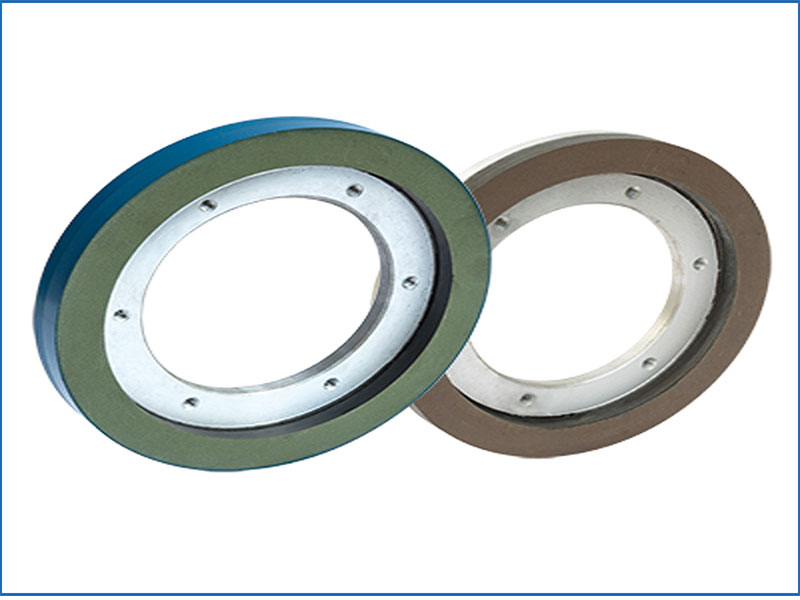

Continuous Rim Diamond Cylindrical wheel

[fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="no" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="" margin_bottom="" padding_top="" padding_right="" padding_bottom="" padding_left=""][fusion_builder_row][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" dimension_margin="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_tabs design="classic" layout="horizontal" justified="yes" backgroundcolor="" inactivecolor="" bordercolor="" icon="" icon_position="" icon_size="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_tab title="Description" icon=""]

Diamond Cylindrical wheel is used to make rough cutting after diamond calibrating roller on ceramic tiles surface. It can also be used to calibrate and achieve a uniform thickness on ceramic tiles surface in replace of Diamond Calibrating Roller. By both rotating of spindle and the cylindrical wheel when working, the high-efficient cutting effect is generated to make ceramic tiles surface more flat and smooth, with which the polishing speed can be increased, the consumption of polishing abrasives can be reduced and the re-polishing rate can be lowered. Out diamond cylindrical wheels are approved for their high cutting efficiency, fine & even cutting mark and good flatness on ceramic tiles surface. According to different production technique it is classified into Continuous Rim Cylindrical Wheels and Segmented Cylindrical Wheels.

Whole sintering craft is adopted to produce this type of cylindrical wheel, continuous rim working area, more fine ceramic tiles surface.

[/fusion_tab][fusion_tab title="Suitable machines" icon=""]

Face Impex tiles are estimated to become some of the most easily reached and most durable ceramic material that makes them economical and easily installable. They come with a thin profile side view as slim as 20mm. Face impex have a big range in small format ceramic water proof tiles with different size and color.

See more ideas about Continuous Rim Diamond Cylindrical wheel with many different color and looks

#Tools and Abrasive

- KEDA,

- ANCORA,

- BMR,

- PEDRINI,

- KEXINDA,

- JCG,

- KELID

- Various porcelain tiles,

- vitrified tiles,

- crystal tiles,

- floor tiles,

- wall tiles etc.

Face Impex tiles are estimated to become some of the most easily reached and most durable ceramic material that makes them economical and easily installable. They come with a thin profile side view as slim as 20mm. Face impex have a big range in small format ceramic water proof tiles with different size and color.

See more ideas about Continuous Rim Diamond Cylindrical wheel with many different color and looks

#Tools and Abrasive