Bell Glazing Series

₹0.00

[fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="no" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="" margin_bottom="" padding_top="" padding_right="" padding_bottom="" padding_left=""][fusion_builder_row][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" dimension_margin="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_tabs design="classic" layout="horizontal" justified="yes" backgroundcolor="" inactivecolor="" bordercolor="" icon="" icon_position="" icon_size="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_tab title="Description" icon=""]

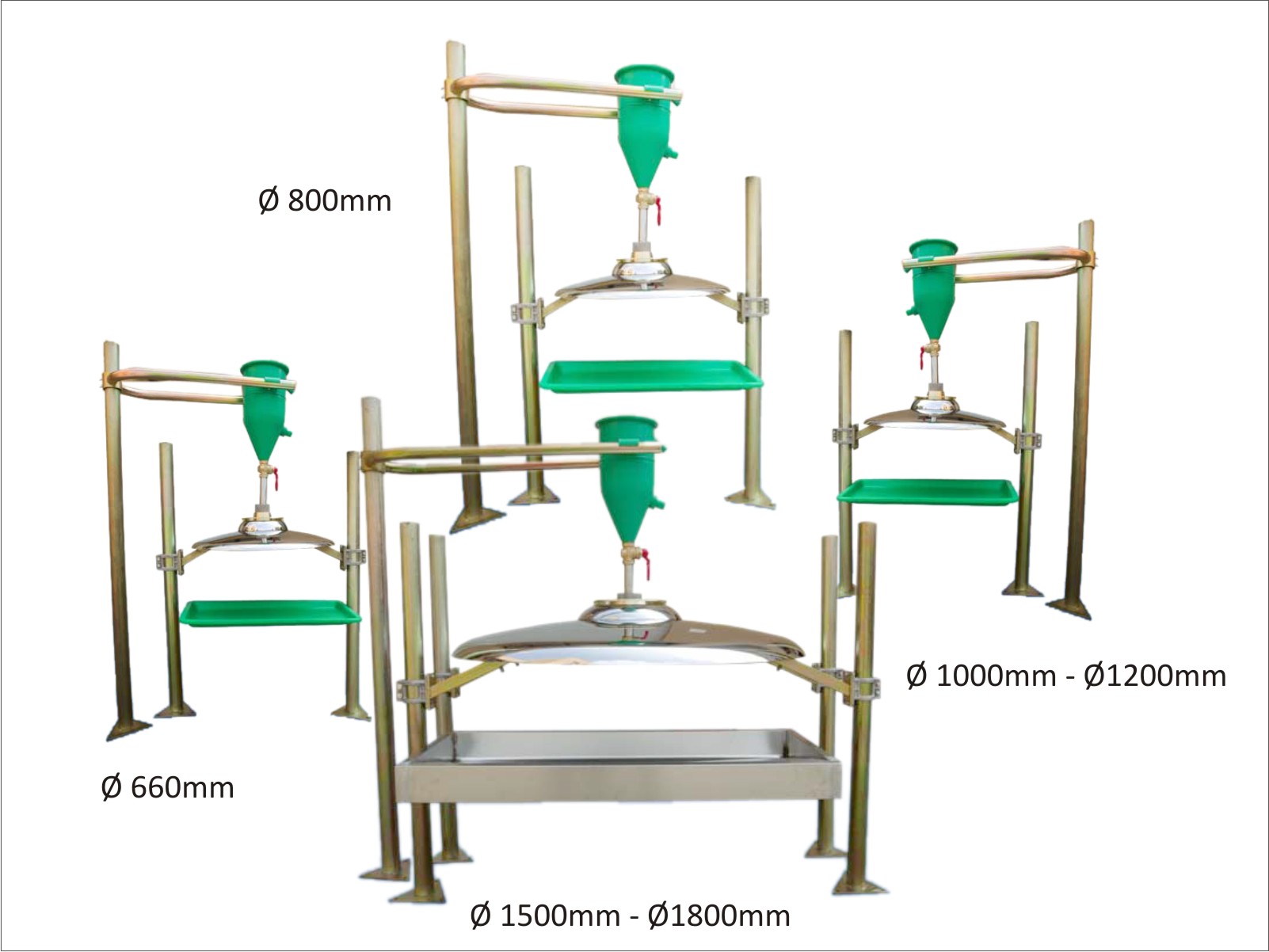

The present invention relates to a "bell-type shower dripper | Bell Glazing Series", and is a device for glazing the surface of a wall tile or a building ceramic. The prior art is a duckbill type shower device, but when the device is glazed, the dimensional accuracy of the rectangular flat mouth of the shower device is very high. The requirements for glaze are also high, otherwise the glaze curtain is not smooth, which greatly affects the quality of glazing. In addition, when the thickness is adjusted by adjusting the width of the rectangular mouth, it is difficult to obtain a desired effect due to the effect of surface tension and the like. In addition, in addition to the fact that the glaze slurry is constantly stirred into the gas during the preparation process, and the subsequent transportation and the degradation of some of the components thereof will generate gas, the degassing measures taken by the device are far from enough. Therefore, bubbles, pinholes and other defects often appear on the green body after glaze firing.

The purpose of the utility model is to provide a bell-type shower dripping device which is uniform in glazing and has few pinholes in bubbles.

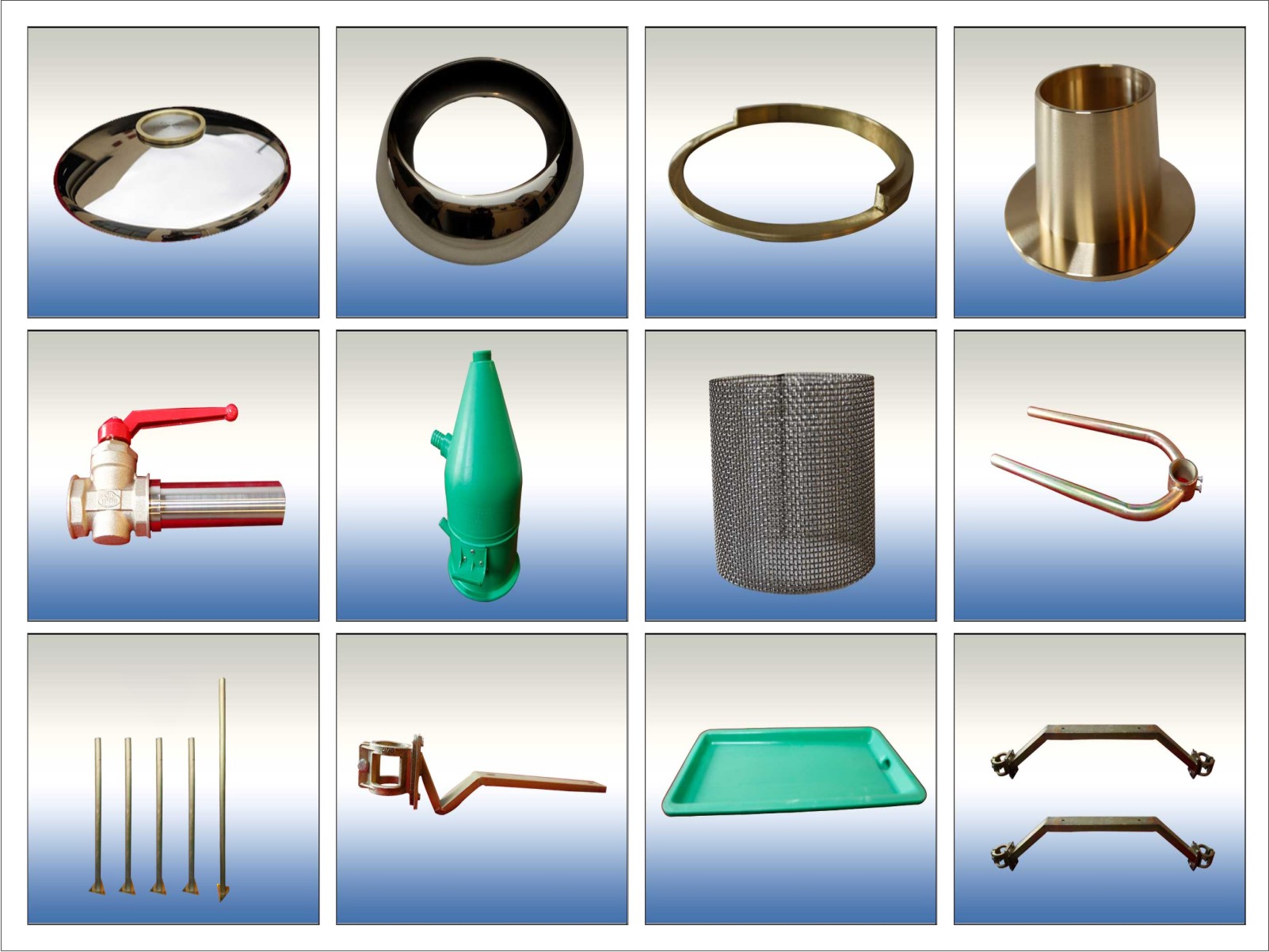

In the technical solution of the present invention, a ball valve 2 is connected to the lower part of the upper funnel 1, a cylindrical filter screen 3 is placed at the lower end of the ball valve 2, a filter box 3 is coated with a column-shaped upper bell jar 5, and the upper bell cover 5 has a shape like The middle bell 6, the upper bell 5 and the middle bell 6 of the bell jar are all placed on the bell jar-shaped lower bell 7 on the surface, and the lower bell bell 7 is on the lower edge and is used for controlling the flow of the glaze liquid. The metal ring 4 is placed on the upper edge of the middle bell 6. The bracket 9 suspends the lower bell 7 above the conveyor belt 10. The enamel disc 8 is placed below the conveyor belt 10.

Working principle Figure 1 shows the structure of the bell shower. A space 12 for storing glaze slurry is formed in the upper bell jar 5, and a space 13 for storing the glaze slurry is formed in the bell jar 6. The glaze slurry flows through the glaze pipe to the upper funnel 1 and maintains a certain glaze position. The hopper 1 flows into the filter net 3 and overflows from the filter net 3 freely. A glaze curtain is formed on the surface 14 of the upper bell 5 to flow into the space 13 in the bell jar 6, and after the space 13 in the bell jar 6 is filled, see In FIG. 4 and FIG. 6 , since the underside of the metal ring 4 has an arc-shaped flat mouth, namely a glaze 23, the glaze overflows from the gap formed between the glaze 23 and the upper edge of the middle bell 6. The outer surface 15 of the arc 6 spreads downward and flows to the arcuate surface 16 of the lower bell jar 7 . Flow through the lower edge of the mouth 11 and flow down from the lower edge of the mouth 11 to form a continuous and uniform curved glaze curtain that falls vertically. When the conveyor belt 10 moves to drive the tile body to pass under the glaze curtain, a glaze is adhered to the surface of the green body.

Referring to FIG. 5 and FIG. 6, if two consecutive shower sleeves are to be performed, two corresponding curved flat mouths, ie, glaze openings 23, can be split at the lower part of the metal ring 4, which can be at the same time at the lower edge mouth 11 of the lower bell cover 7. Two glaze curtains are formed, and the passed green body is glazed twice in succession. The excess glaze slurry flows into the enamel disc 8 and can be collected and collected by the bottom glaze pool.

The advantage of the utility model lies in that, compared with the duckbill shower device, the glaze slurry flows from the inner surface into the outer surface, and the linear glaze curtain becomes an arc. In addition, it can also be glazed twice in succession. The bell surface is designed as an arc according to the mathematical model of the fluid, the glaze slurry can maintain a continuous and stable flow on it; the degassing device is adopted to improve the internal quality of the glaze layer; the glaze paddle from the upper bell 5 and the bell jar 6 The upper edge of the overflow overflows the vortex. In order to facilitate the elimination of gas, the arc surface of the lower edge of the bell jar 7 is approached vertically downward and processed into a cutting edge. Easy to drop the glaze.

[/fusion_tab][fusion_tab title="Advantage" icon=""]

1. According to the flow characteristics of the glaze, the shape of the surface of the bell jar and middle bell cover is designed as a streamlined surface, so that the glaze slurry flows smoothly.2. The three-bell showering glaze method ensures the flow time of the glaze slurry in the glaze device, which is not only favorable for the elimination of gas and impurities in the glaze slurry, but also conducive to the smooth spreading of the glaze slurry.

3. The lower edge of the lower bell cover 7 is designed as a cutting edge to ensure continuous and stable glaze curtain.

4, in the upper bell 5 and the upper funnel 1 with a filter to play the role of degassing slag, improve the intrinsic quality of the glaze.

5. The upper funnel 1 keeps the glaze curtain continuous and stable.

6. The utility model significantly improves the uniformity and stability of the glaze, improves the intrinsic quality of the glaze, and improves the glazed quality of the tiles.

[/fusion_tab][/fusion_tabs][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

Face Impex tiles are estimated to become some of the most easily reached and most durable ceramic material that makes them economical and easily installable. They come with a thin profile side view as slim as 20mm. Face impex have a big range in small format ceramic water proof tiles with different size and color.

See more ideas about Bell Glazing Series with many different color and looks

#Machinery

Face Impex tiles are estimated to become some of the most easily reached and most durable ceramic material that makes them economical and easily installable. They come with a thin profile side view as slim as 20mm. Face impex have a big range in small format ceramic water proof tiles with different size and color.

See more ideas about Bell Glazing Series with many different color and looks

#Machinery