[fusion_builder_container hundred_percent="no" hundred_percent_height="no" hundred_percent_height_scroll="no" hundred_percent_height_center_content="yes" equal_height_columns="no" menu_anchor="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="center center" background_repeat="no-repeat" fade="no" background_parallax="none" enable_mobile="no" parallax_speed="0.3" video_mp4="" video_webm="" video_ogv="" video_url="" video_aspect_ratio="16:9" video_loop="yes" video_mute="yes" video_preview_image="" border_size="" border_color="" border_style="solid" margin_top="" margin_bottom="" padding_top="" padding_right="" padding_bottom="" padding_left=""][fusion_builder_row][fusion_builder_column type="1_1" layout="1_1" spacing="" center_content="no" link="" target="_self" min_height="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id="" background_color="" background_image="" background_position="left top" background_repeat="no-repeat" hover_type="none" border_size="0" border_color="" border_style="solid" border_position="all" padding_top="" padding_right="" padding_bottom="" padding_left="" dimension_margin="" animation_type="" animation_direction="left" animation_speed="0.3" animation_offset="" last="no"][fusion_tabs design="classic" layout="horizontal" justified="yes" backgroundcolor="" inactivecolor="" bordercolor="" icon="" icon_position="" icon_size="" hide_on_mobile="small-visibility,medium-visibility,large-visibility" class="" id=""][fusion_tab title="Description" icon=""]

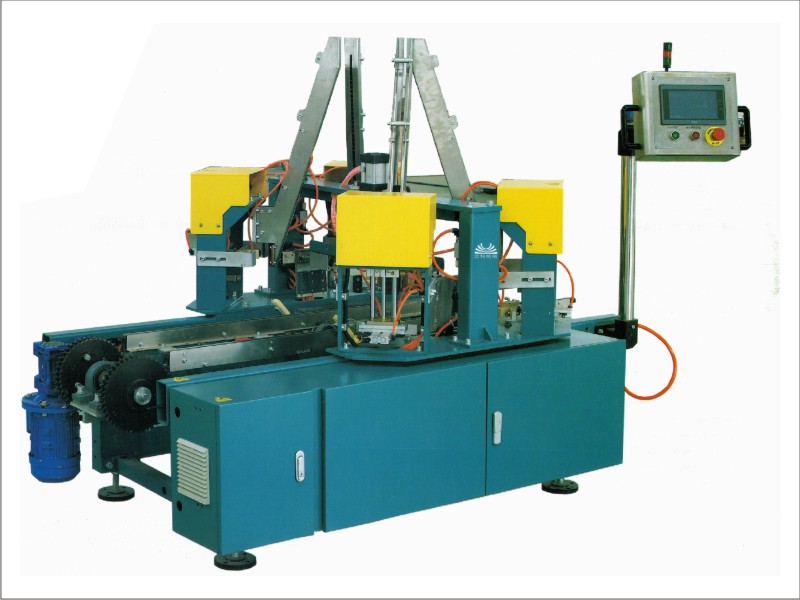

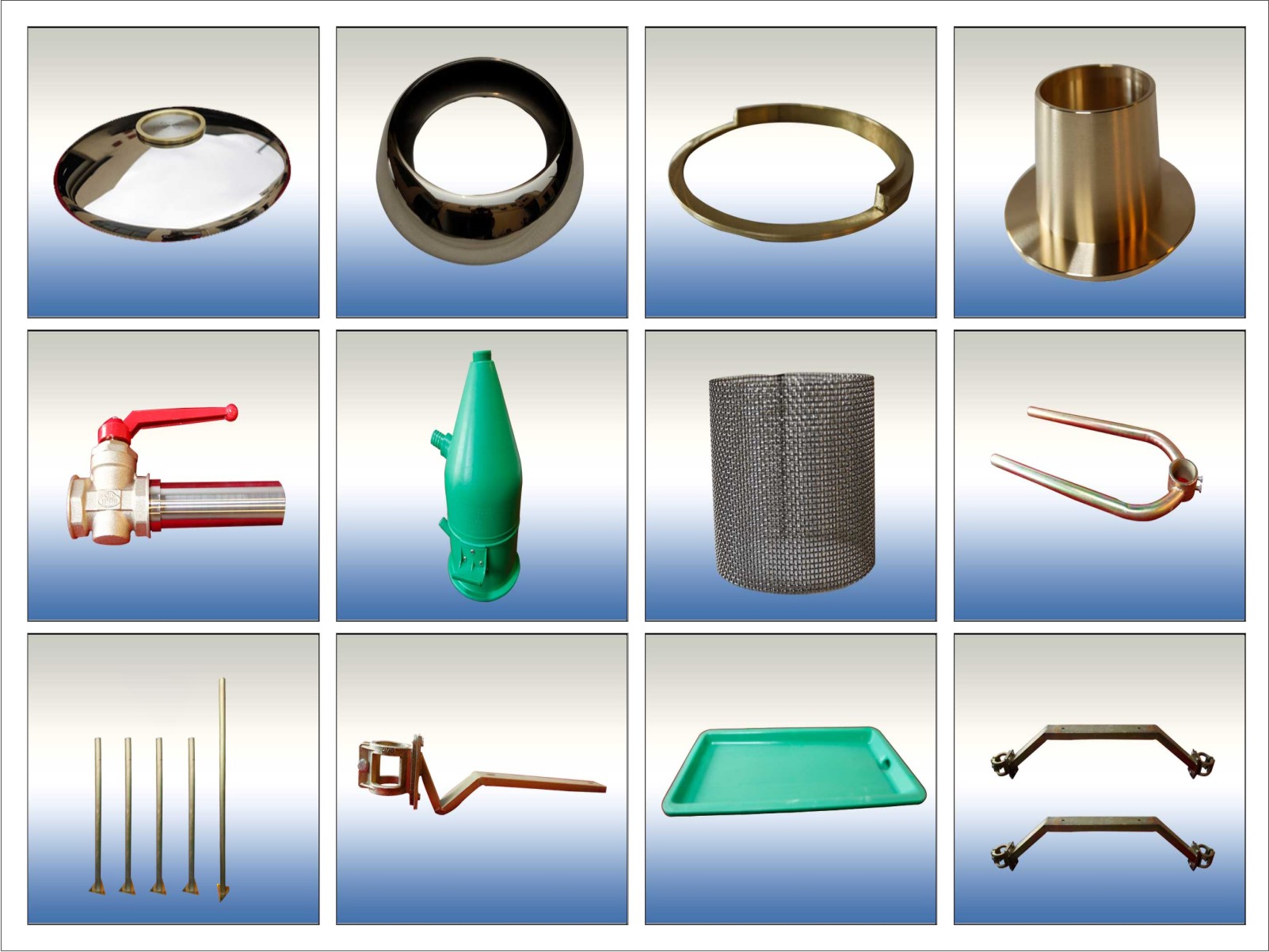

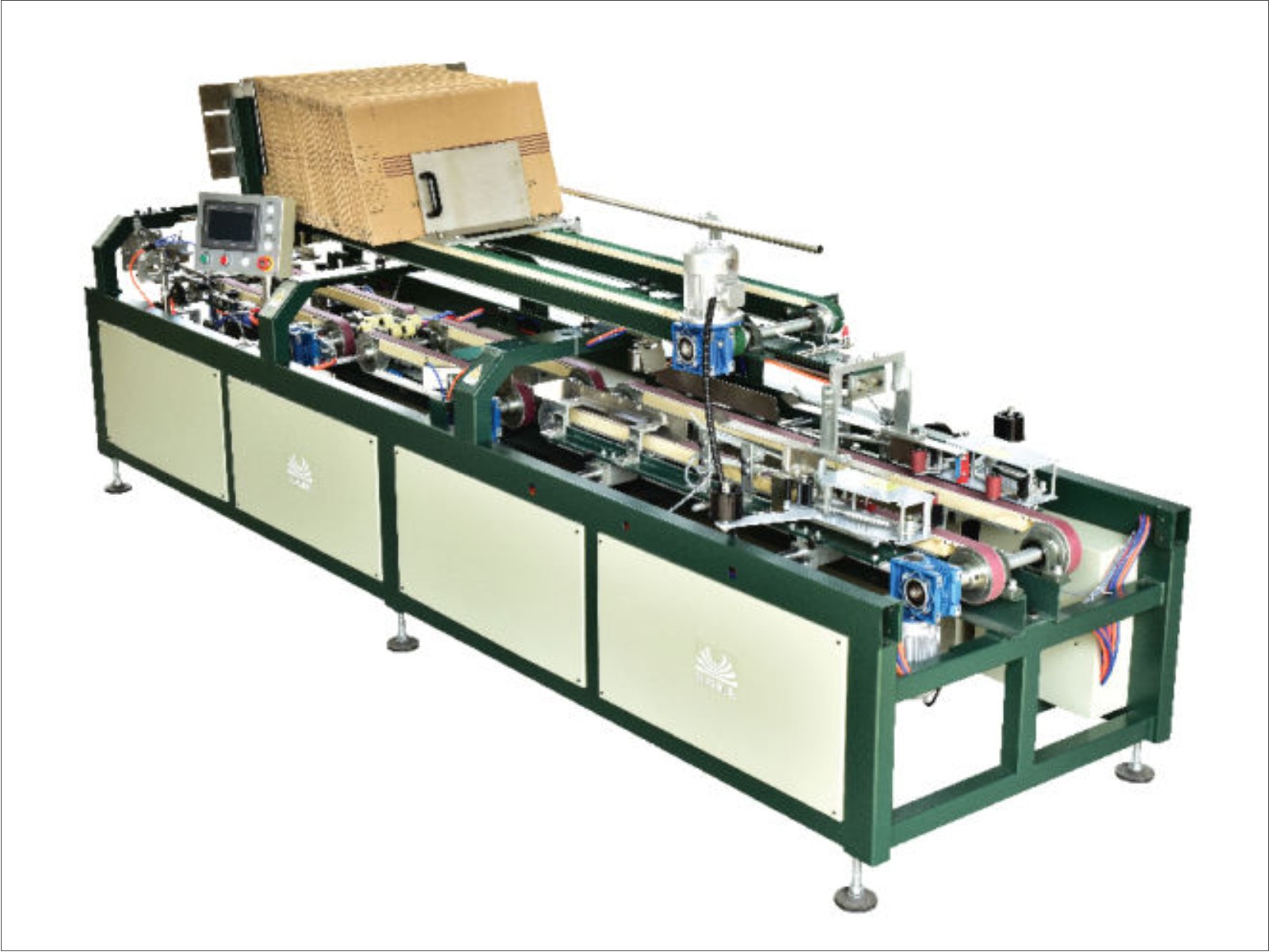

This equipment is a combination of the characteristics of the use of the ceramic industry and production experience, the use of modern mechanical and electrical integration of automation technology, after years of research and development of the new generation of green body polishing thick machine has become very complete and effective machinery and equipment due to high processing efficiency, applicability the use of low cost, safe and convenient operation, and by the ceramic industry users well received.

[/fusion_tab][fusion_tab title="Technical Parameters" icon=""]

Biscuit polishing machine configuration Technical Parameters

| Model |

PDH800-4 |

|

|

| Biscuit machine Specifications |

L5.8M*W1.7M*H2M |

|

|

| Working width |

500mm~950mm |

Working voltage |

380V/50HZ |

| Working thickness |

3mm~40mm |

|

first group |

7.5KW |

| Belt line speed |

0~35m/Min |

Belt motor power |

second group |

5.5KW |

| LoadingTiles speed |

0~35m/min |

|

third group |

5.5KW |

| Working pressure |

0.25~0.5Mpa |

conveyor motor power |

2.2KW |

| Compressed air consumption |

1.5m3/min |

Total motor power |

20.7KW |

| Belt size |

450mmx1930mm |

weight |

2200kg |

[/fusion_tab][fusion_tab title="Cost Analysis" icon=""]

Biscuit polishing machine in use cost analysis

| Expenditure |

|

Benefit |

|

| Electricity |

Rmb 0.035 / sqm |

Excellent rate of |

>=2% |

| Consumables |

Rmb 0.010 / sqm |

Glaze reduction of |

6%~15% |

| Comprehensive reflection of the tiles surface defects |

| Before polishing on green body |

1.unpolished surface roughness (burr, granules) |

After polished on green body |

NO HAVE |

|

2. dirty drop |

|

NO HAVE |

|

3. scratches |

|

NO HAVE |

| surface defects of before glazing and no polishing |

Wave |

Surface of After glazed |

no wave pattern |

|

2.orange peel |

|

reduced orange peel |

|

3. glaze of low brightness |

|

Glaze with strong brightness |

|

Use more glaze material |

|

Reduce the amount of the glaze quantity |

[/fusion_tab][/fusion_tabs][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

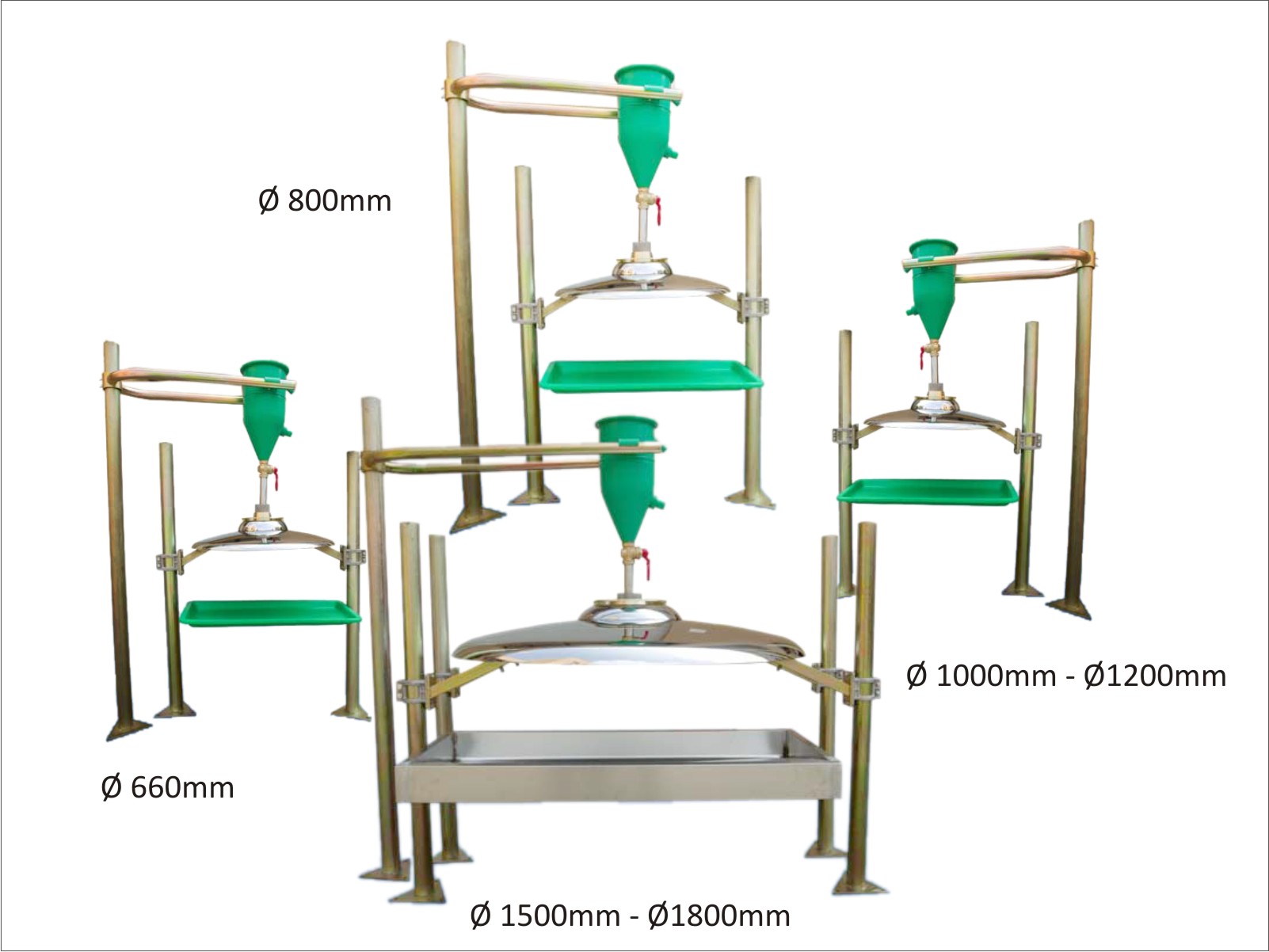

Face Impex tiles are estimated to become some of the most easily reached and most durable

ceramic material that makes them economical and easily installable.

They come with a thin profile side view as slim as 20mm. Face impex have a big range in small format ceramic water proof tiles with different size and color.

See more ideas about GVT/PGVT GREEN BODY THICKNESS POLISHING MACHINE with many different color and looks

#Machinery